We're the home for inclusive and accessible playgrounds, let's play.

Read the Latest Community Stories about Inclusion

Every week we curate the latest community stories about inclusive playgrounds: newly open playgrounds, fundraising events, groundbreakings. It is our hope that you can learn from what other communities are doing.

Accessible and Inclusive Playground Directory

The directory will help you and your family find wonderful places to play around the country. We need your help if you know of an accessible or inclusive playground. You can add an inclusive playground.

Check out some of our favorite playgrounds!

=

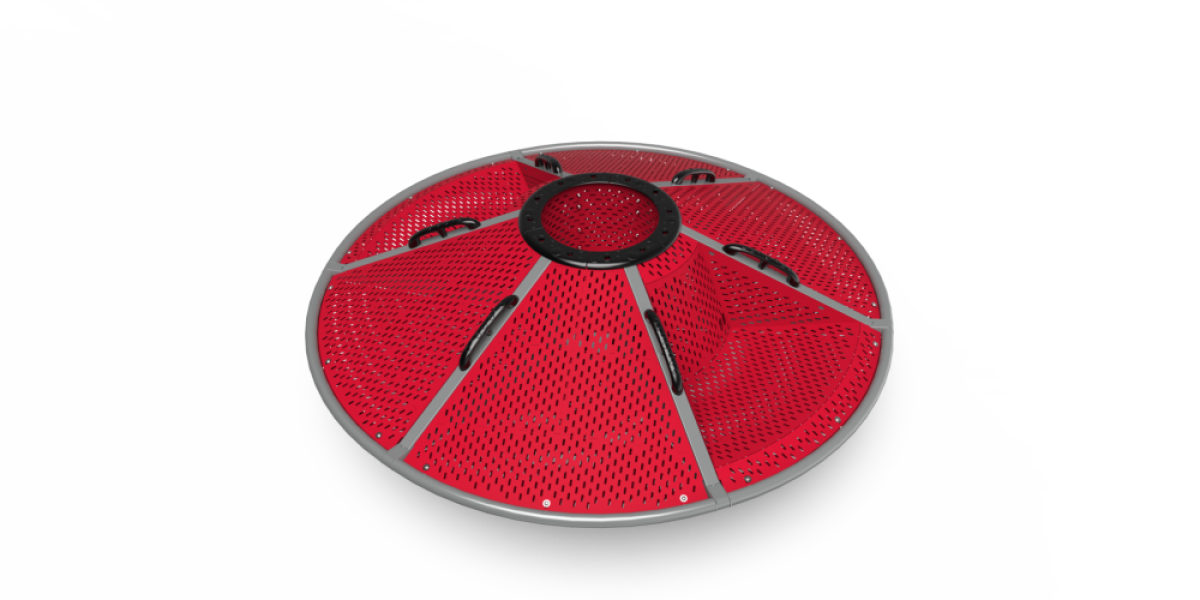

Check out some of our favorite pieces of equipment

What do all the different terms mean?

There are many terms that define a playground where children of all abilities can play. For the most part they are interchangeable. However, there are some differences.

Accessible Playground

Accessible means to be reached or entered. Accessible playgrounds are those that have gone beyond ADA to ensure that people using wheelchairs can use the playground.

Inclusive Playground

Inclusion is ensuring that people feel they belong, are engaged, and connected. Inclusive playgrounds are ones designed specifically to ensure that children of all abilities can play together. It goes way beyond wheelchair access. All inclusive playgrounds are accessible, but not accessible playgrounds are inclusive.

Universal Designed Playgrounds

Universal design refers to a broad-spectrum solution that produces environments that are usable and effective for everyone. MORE INFORMATION

ADA Compliant Playground

This is a playground that meets all of the American with Disability Act regulations for playgrounds. It is the least you can do according to the law. We believe that ADA is not nearly enough to ensure that all kids can play.

Parents tend to use the terms “Playgrounds for all Abilities” or “Playgrounds for children with disabilities”

Handicapped Playgrounds, Handicapped-Accessible Playgrounds, Wheelchair Playgrounds are outdated terms that most people do not use.

Parents tend to use the terms “Playgrounds for all Abilities” or “Playgrounds for children with disabilities”

Handicapped Playgrounds, Handicapped-Accessible Playgrounds, Wheelchair Playgrounds are outdated terms that most people do not use.

3 comments on “Welcome!”